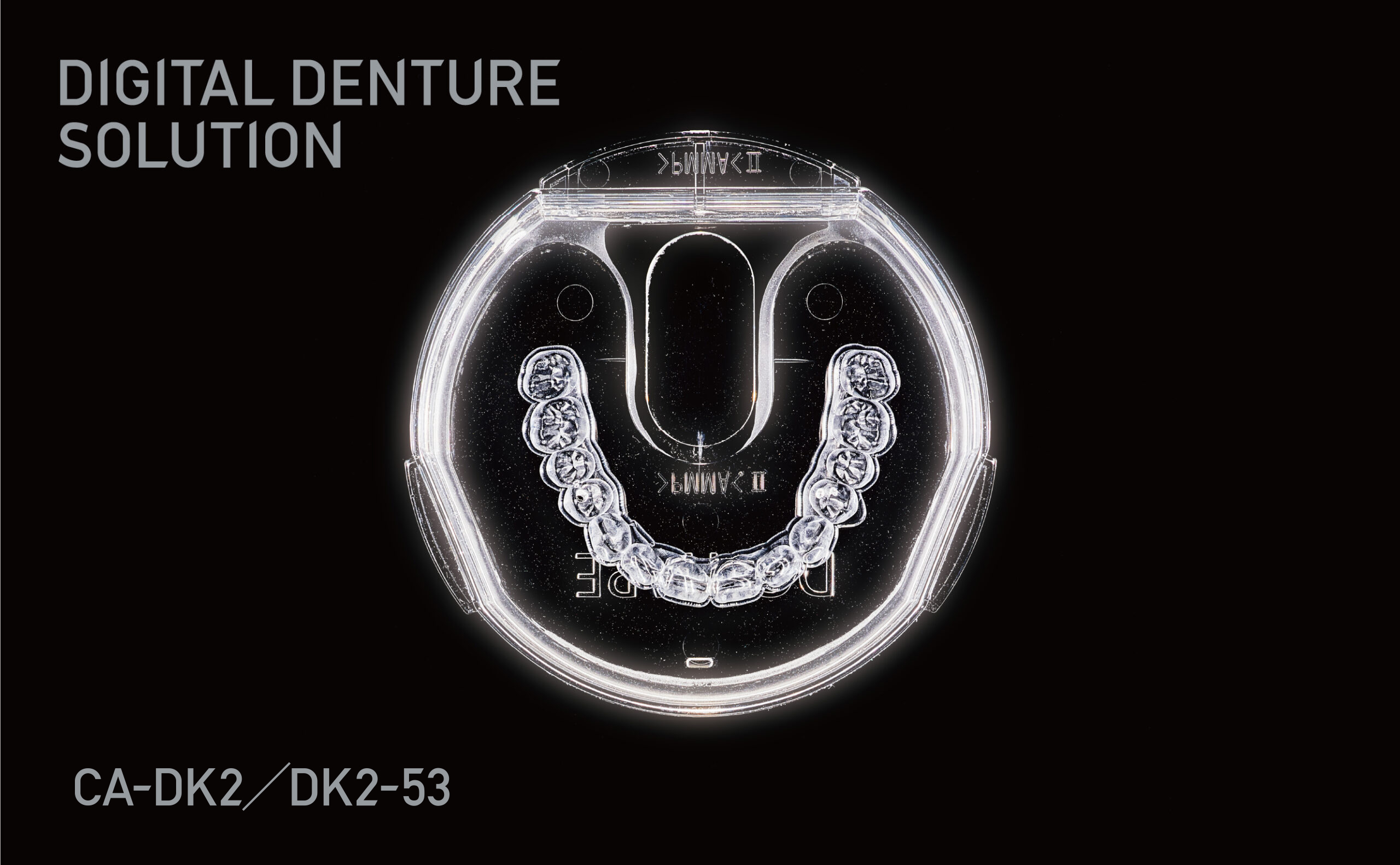

Denture Kit

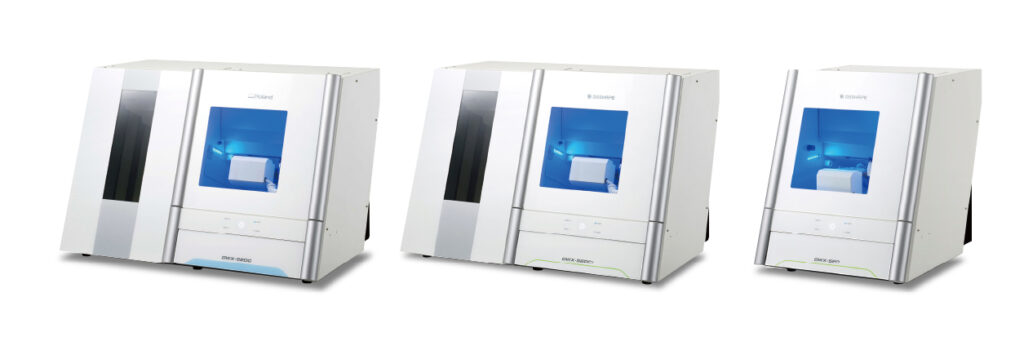

for DWX Dry Dental Mills

Shape Smiles for All

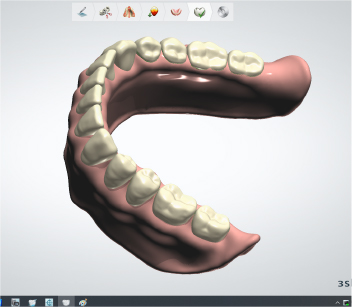

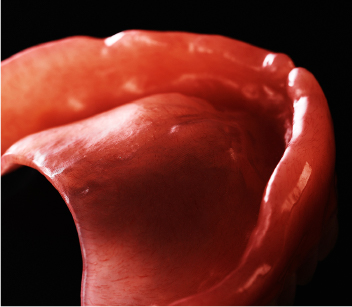

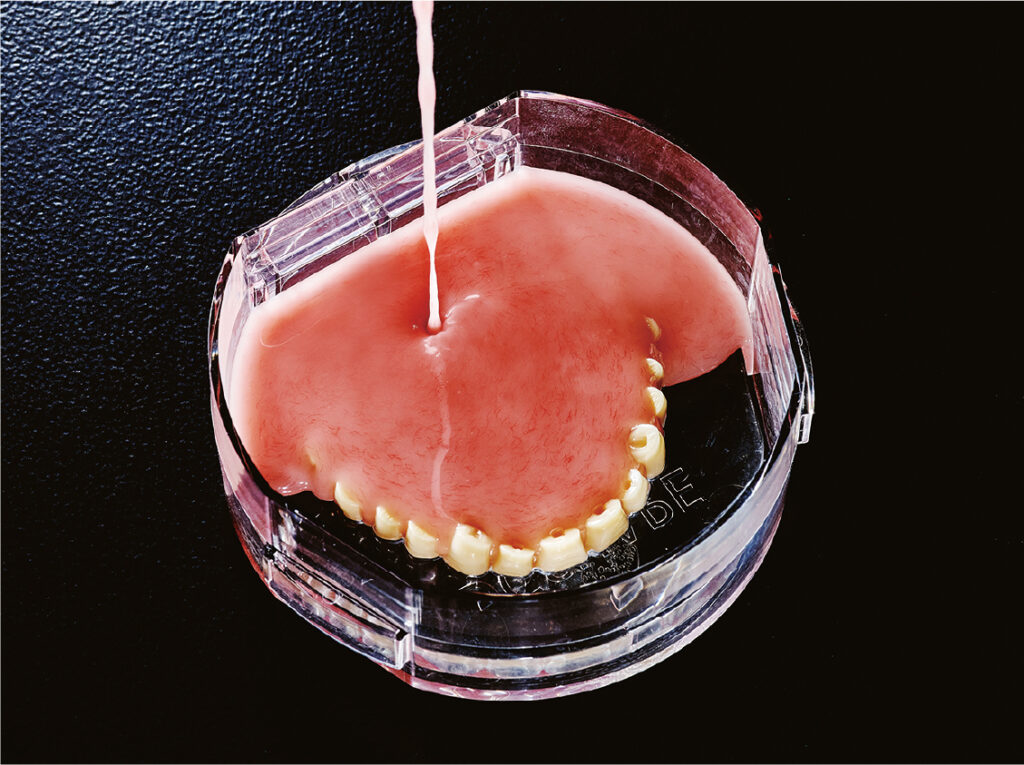

DGSHAPE’s Denture Kit lets you choose to produce custom dentures with heat-cured or cold-cured acrylic. Carded, milled, or printed teeth are set in minutes as tooth pockets are milled into the denture base to ensure ease of sitting. Take the process a step further using the carded tooth tray and produce an aesthetic, full denture in less than four hours. Along with offering a choice of workflows, using the denture kit lowers production costs and improves turnaround times while providing high-quality output, making it the ideal digital denture solution.

Tooth-setting simplified

Easily fit carded, milled, or printed teeth into milled pockets

Affordable aesthetic solution

Create aesthetically pleasing, custom-made full dentures in-house and save money instantly

Faster turnaround time

Employ this digital workflow and put the time you save back into your business

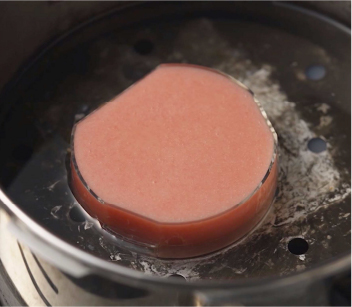

Heat-cured compatible

Choose to use heat-cured or cold-cured acrylic with your denture kit

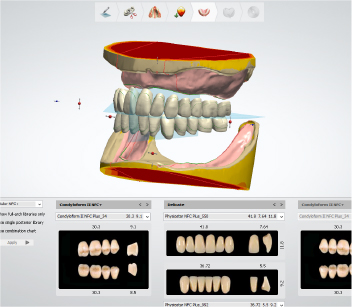

Open solution

The denture kit is compatible with the latest CAD software, including 3Shape’s Dental System and exocad

Catalog(PDF)Download

Choose between two types of workflows

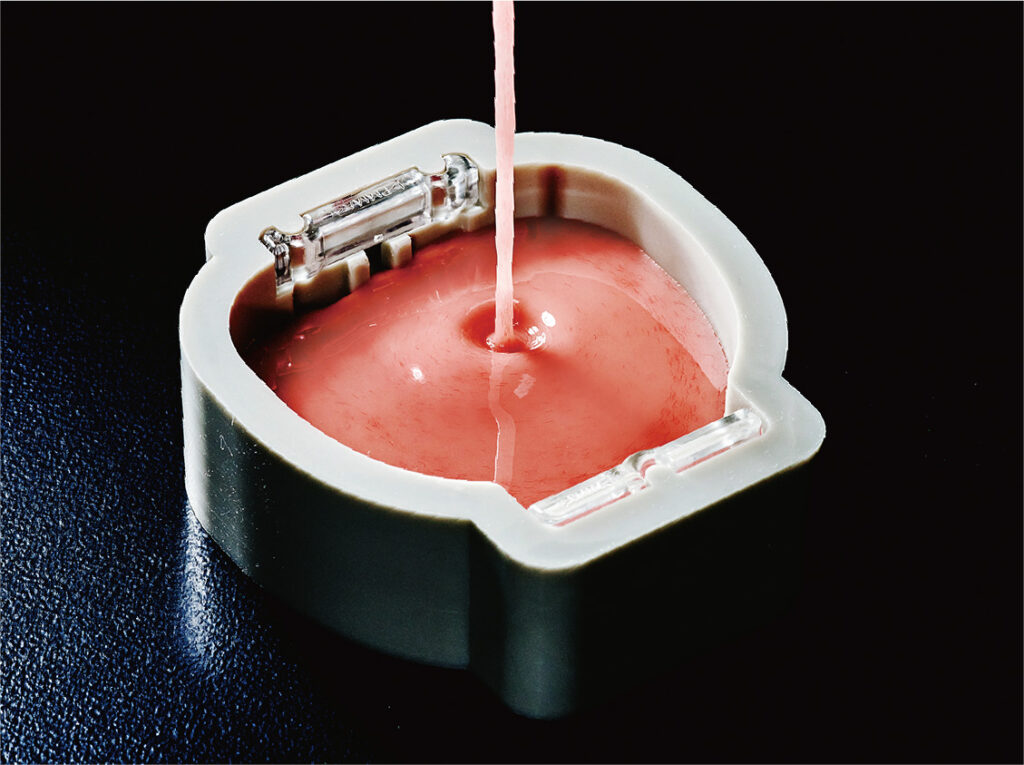

❶Denture Base workflow

❶Design using CAD software

❷Polymerize the cold- or heat-cured acrylics

❸Mill the acrylic base using your DWX device

❹Manually place the carded teeth

❺Polish and finish

*The workflow with heat-cured acrylic is different.

*Please refer to the support page for manuals and videos that provide workflow details.

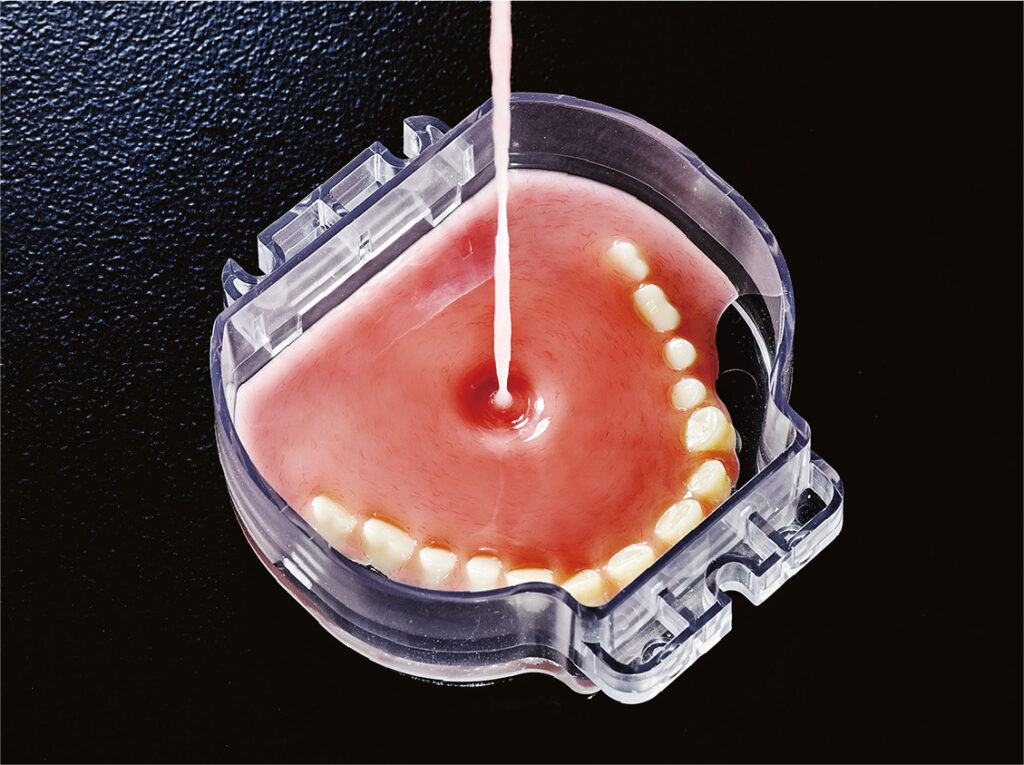

❷Removable Denture workflow

❶Design using CAD software

❷Mill tooth sockets using your DWX device

❸Manually place the carded teeth

❹Polymerize the cold- or heat-cured acrylics

❺Mill the acrylic base and teeth using your DWX device

❻Polish and finish

*The workflow with heat-cured acrylic is different.

*Please refer to the support page for manuals and videos that provide workflow details.

Choose between three types of denture kits

Compatible dental mills:DWX-52DCi / DWX-52DC / DWX-52D

CA-DK2 is the Denture Kit for DWX-52 series devices.

DWX dental mills provide high precision for milling dentures.

The optimized tray shape and 3mm roughing tool reduce material costs and milling time.

CA-DK2 is compatible with both the Denture Base workflow and the Removable Denture workflow.

Work time with Denture Base workflow

![]() Manual work time: 50 mins

Manual work time: 50 mins

![]() Milling time: 2 hrs 45 mins*

Milling time: 2 hrs 45 mins*

*Milling time varies according to denture size and DWX model.

Work time with Removable Denture workflow

![]() Manual work time: 25 mins

Manual work time: 25 mins

![]() Milling time: 3 hrs 45 mins*

Milling time: 3 hrs 45 mins*

*Milling time includes sockets milling. Milling time varies according to denture size and DWX model.

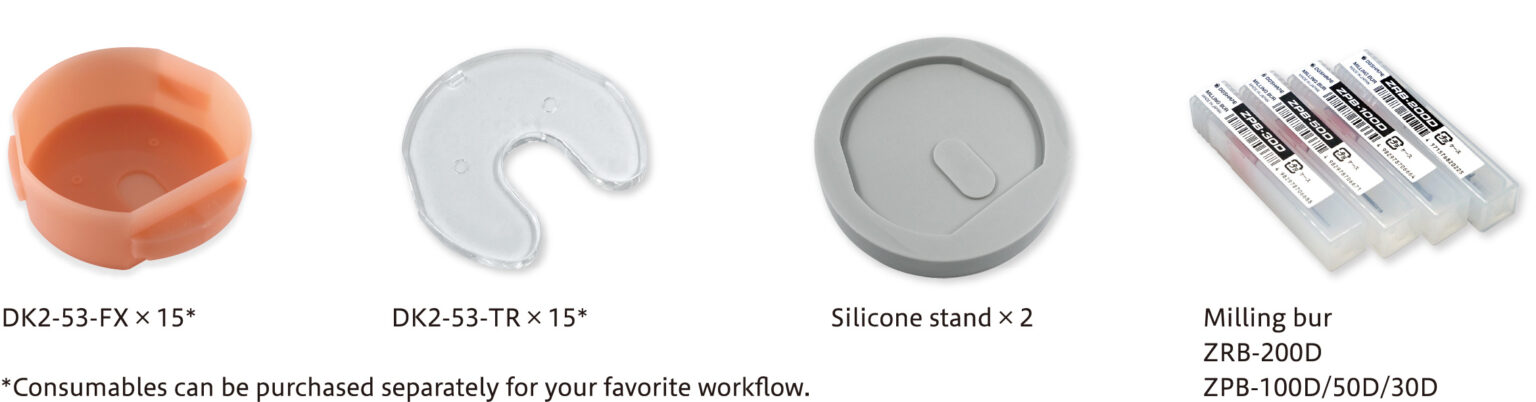

Compatible dental mill:DWX-53DC

DK2-53 is the Denture Kit for the DWX-53DC, the latest DGSHAPE device which features strengthened rigidity and a newly designed spindle for high performance denture milling.

4mm roughing tool reduces milling time.

DK2-53 is compatible with both the Denture Base workflow and the Removable Denture workflow.

Work time with Denture Base workflow

![]() Manual work time: 50 mins

Manual work time: 50 mins

![]() Milling time: 2 hrs 15 mins*

Milling time: 2 hrs 15 mins*

*Milling time varies according to denture size and DWX model.

Work time with Removable Denture workflow

![]() Manual work time: 25 mins

Manual work time: 25 mins

![]() Milling time: 3 hrs 15 mins*

Milling time: 3 hrs 15 mins*

*Milling time includes sockets milling. Milling time varies according to denture size and DWX model.

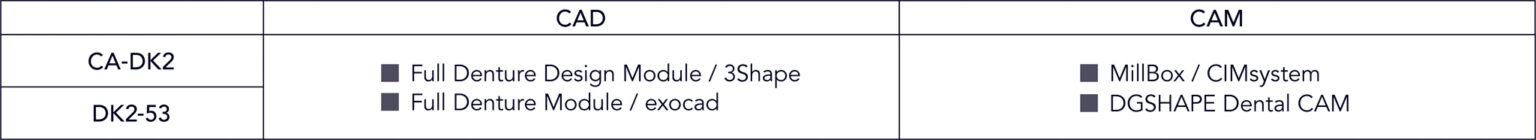

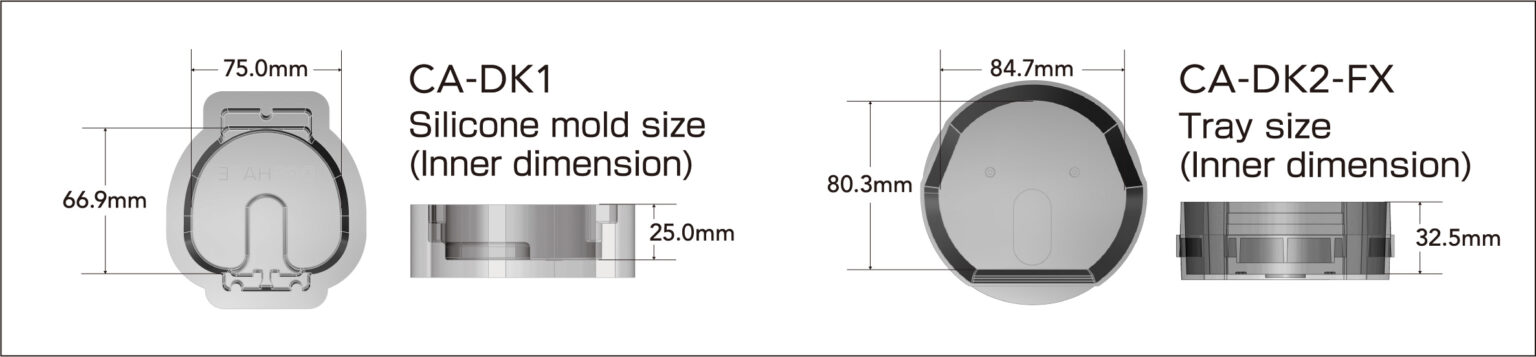

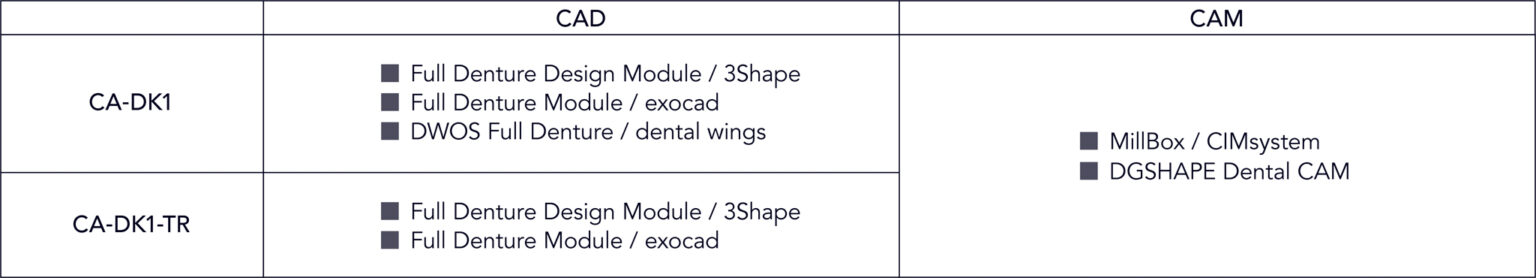

Compatible CAD/CAM

Compatible dental mills:DWX-53DC / DWX-52DCi / DWX-52DC / DWX-52D

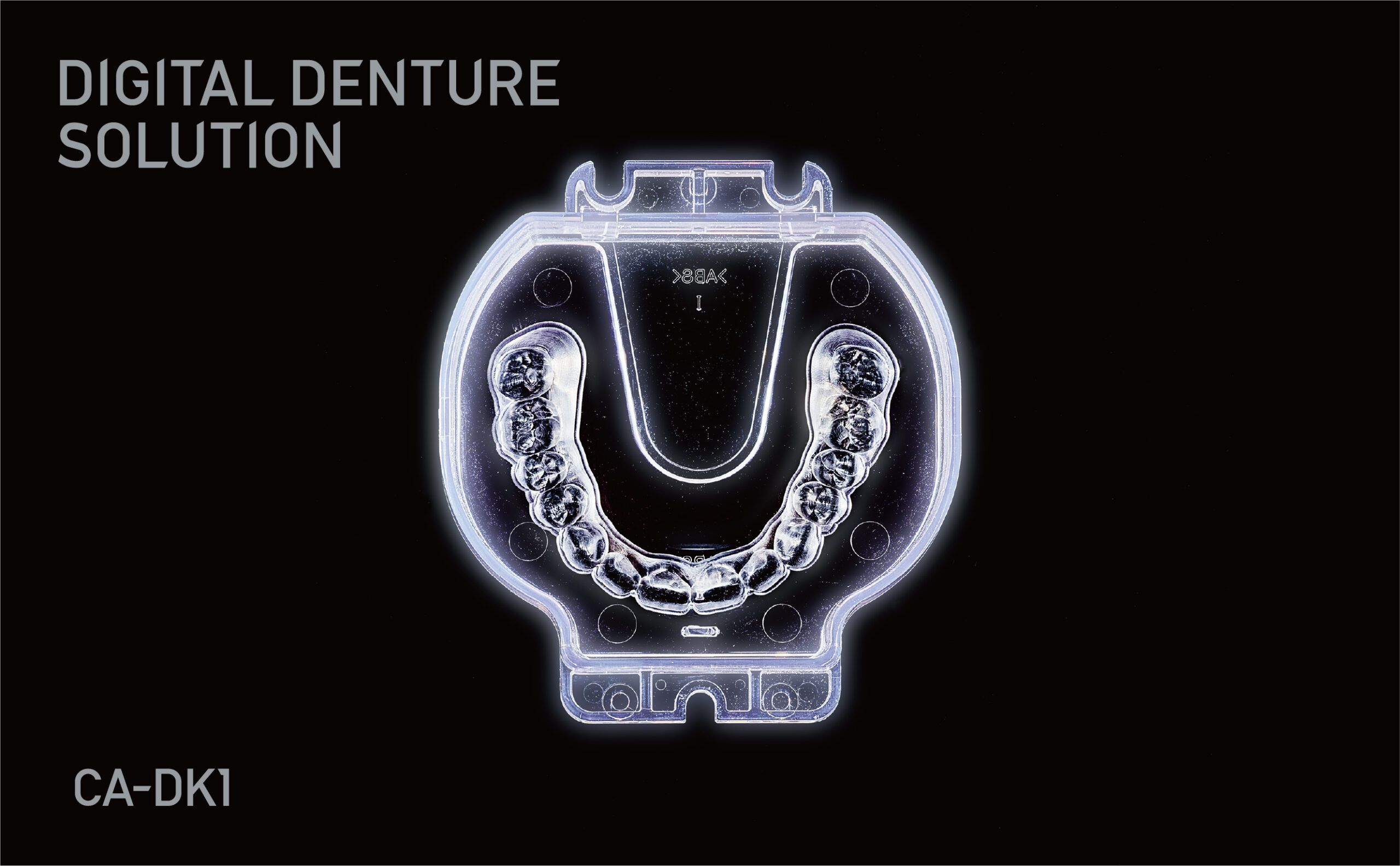

Denture Kit for small cases

■The smaller silicone shape reduces milling time and material costs.

Denture Base Workflow

Requirements

Removable Denture workflow

Requirements

*Removable Denture workflow with CA-DK1 and CA-DK1-TR is not compatible with heat-cured acrylics.

*Please refer to the support page for manuals and videos that provide workflow details.

Compatible CAD/CAM

Customer Stories

CA-DK1

Dr. Jae-min Lee(Mirero Dental Clinic)

CA-DK1-TR

Dr. Jae-min Lee(Mirero Dental Clinic)

DGSHAPE Digital Denture Webinar

Interested? Request a free demo

Find a Dealer

Our DGSHAPE Authorised dealers are carefully selected, and offer superior expertise and tailored advice across a range of DGS products and services.

By filling out the form, we can ensure:

- A no-hassle process, a dealer will contact you right away

- We match your needs to the dealer who has the best expertise to support your business CAD/CAM needs in the base of your country

- You won’t waste time trying to find the right dealer around the world

- You are buying genuine, authentic DGSHAPE services and supplies